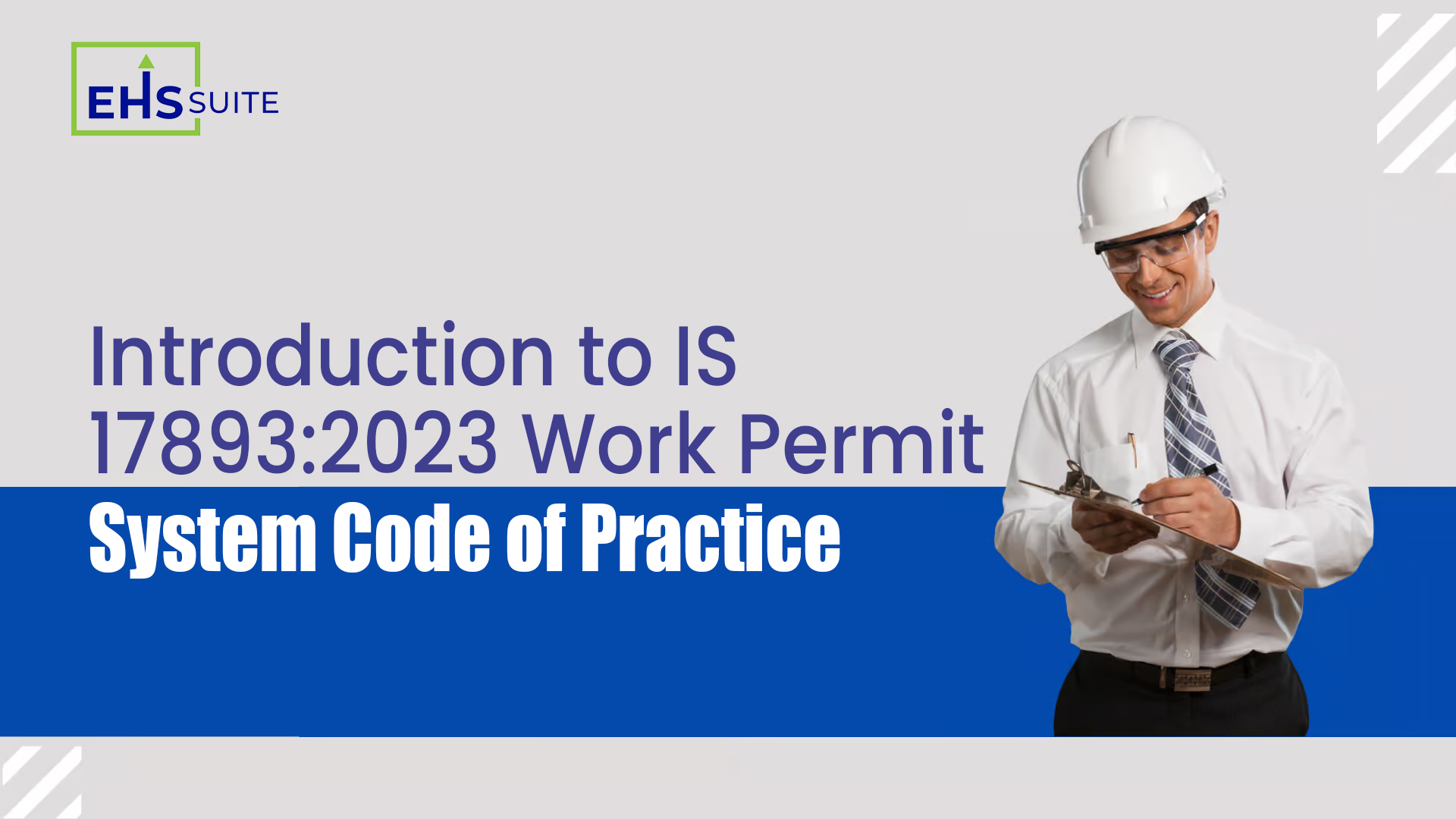

Introduction to IS 17893:2023 Work Permit System Code of Practice

What is IS 17893:2023 Work Permit System Code of Practice?

In order to standardise and regulate the work permit system in various industries, the Bureau of Indian Standards has issued a unified standard code IS 17893:2023. The code makes it easier for organisations to ensure the smooth functioning and safety compliance of the work permits.

Work permits are authorised documents for allowing operations in certain hazardous working environments. They provide a checklist for a systematic method of risk assessment because it warns of the residual hazards in the job. They also outline the precautions to take while working to achieve the stated objectives.

How is it applicable to you?

A permit-to-work is essential for industries dealing with life-threatening or risky activities. Construction, manufacturing, electrical work, mining, etc., are examples of industries that clearly qualify for a work permit before initiating activities. However, there is a list of areas that require a work permit to ensure a safe and healthy working environment.

A permit-to-work is applicable to you if your organisation deals in any of the following permit areas:

- Cold work permit

A cold work permit applies to activities that do not produce enough heat and inflammable substances but may involve a risk of injury. It is required in all hazardous activities that do not qualify for any other permit activities.

- Hot work permit

A hot work permit is required at places where there is a presence of fire hazards, sources of ignition, and flammable or combustible substances.

- Confined space/ vessel entry permit

Permits for Confined Space Work are required when entering or investigating a confined space, like a trench, tank, or vessel.

- Excavation permit

An excavation permit is applicable at sites of operations that involve excavating and mining the ground in order to construct or remove materials from it.

- Electrical work permit

An electrical work permit is applicable to places where the work requires making contact between the worker and an electrical source.

- Work at height permit

A work-at-height permit is required at places where the workplaces are elevated at over 2 metres height because it includes working with ladders, scaffolds, MEWPs or working off the ground.

- Radiography

A permit is applicable at the sites where any of the following may take place: radiation on pipelines/equipment, isolation and restoration of a radioactive source.

As per IS 17893:2023 permit-to-work is not required for the following activities:

- Routine welding/cutting or similar maintenance/ fabrication work carried out in/around any plant unit workshops, or any area demarcated by the facility manager;

- Analyzing routine samples in a laboratory;

- Canteen for cooking, preparing tea/food, etc.

- Torches, furnaces, and sparking devices designated in certain areas of a laboratory;

- Gathering trash from designated safe sites within the plant area;

- All cold jobs in office buildings including control room buildings. However, a work permit is of need in certain regions involving excavation, work at height, or electrical isolation;

- Visual examination of the plant’s rotating or stationary equipment by maintenance or inspection staff;

- Replacement of tube light rods inside the building. However, It is necessary to get verbal approval from the area/shift manager before beginning work;

- Hand mowing grass with a hand mower, pruning branches, etc., surrounding office buildings, control rooms, plant areas, and non-plant areas. However, the appropriate work permit is required for tasks involving electrical connections, as well as heights or excavating deeper than 30 centimetres; and

- Any additional regular actions which are approved by the facility manager through a different notification.

General procedure for the work permit system

The work permit system – code of practice specifies a general procedure for work permits that is applicable to everyone who is issuing it:

- The permit issuer oversees and manages the complete work permit procedure.

- The permit is in triplicate.

- The first copy is the acceptor’s/ executor’s copy, which should be displayed at the job location.

- The issuer keeps the second copy for work-related tasks and documentation purposes.

- The third copy of the permit is retained with the safety department.

- Either the issuer or the acceptor requests for a permit-to-work. The issuer is the shift in charge of the area, and the acceptor has responsibility for the execution of the work.

- Before filling up the necessary details in the work permit, the issuer and acceptor jointly make a risk assessment of the job and agree on the following:

- Particular protocols to be followed when carrying out the task;

- Prerequisites should meet prior to the task being completed; and

- Unique requirements, such as personal protective equipment (PPE), etc.

- If the work is to be continued beyond the specified hours, then it is done by continuing or renewing the work for the next day based on the approval of specific authorities and the type of work.

- If the working environment is unfavourable or if the conditions differ from those specified in the work permit, then the job may be suspended at any time.

- It is mandatory for plant authorities to provide training for work permit processes to their personnel so that they can perform the various tasks specified in the procedure.

Common requirements for work permit system formats

The work permit system format consists of multiple sections to help the issuer identify potential risks and protocols that have been in use to complete the task safely.

The following are specifics of various items in the different sections of the permit:

1. Job Particulars

This section includes the various details about the job.

- The manufacturing unit or plant;

- Area/ section of the facility belonging to a plant;

- The person/ agency entrusted to carry out the work;

- Date and time;

- The person/ employee’s name and designation along with the department;

- Equipment tag number and equipment name;

- Specific limitations of the work permit;

- Specific instructions to work permit holder;

- The details of work related to maintenance, construction, inspection, etc to be carried out; and

- The name of the contractor who is responsible for executing the job.

2. Nature of Job

Identifying the nature of the job is essential to deciding the appropriate safety protocols during the work. This section requires the issuer to choose whether the operation involves creating flames, or sparks, or requiring a vessel entrance permission for hot work or vessel entry.

If it isn’t included under one of these job types, the issuer can choose “other” and include the activity.

3. Personal Protection Equipment (PPE)

Working personnel have to to wear safety equipment like helmets, goggles, hand gloves and shoes in their respective work areas. The list of PPEs for the specific job are mentioned in the permit. These equipment including the additional PPEs are arranged by the agency undertaking the work. The following are common PPEs:

- Hand gloves

- Ear and head protection

- Eye and face Shield

- Full body double lifeline safety harness

- Body protection

- Foot/ leg protection

- Online air-breathing apparatus

- Airline mask/SCBA/cartridge gas mask

- Dust mask

4. Gas Test

A gas test for oxygen content, hydrocarbon content and toxic content is carried out by the permit issuer in confined spaces. The corresponding permits must include the name and time of the person-carrying test. For welding jobs, it is necessary that a gas test be conducted for hydrocarbon content within a radius of 5.0 metres from the work site.

The gas test is done prior to the issuance of the permit-to-work and reported by the authorised plant personnel. These tests are required to be done at regular intervals, at every renewal and revalidation of the work permit.

Corrective actions are required to be taken if any gas test indicates the presence of flammable, toxic gas vapour or oxygen deficiency when they exceed the permissible limits.

5. Approvals

The permit is ultimately approved by the issuer and the job executor upon compliance with the points in the checklists and any other special precautions/procedures (such as the gas test, etc.). The HOD of the plant is responsible for approving excavation, vessel entry, and hot work permits. Job issuer or executor shall mention the name of the contractor if a contractor because he is responsible to execute the task.

6. Closures and Cancellation

- Closure of work permit

The permit must be closed after the completion of work in a timely manner. A permit-to-work can extend for a period of 7 days, after which the permit is in renewal. A new permit is issued even if there is a work break for more than one calendar day. Upon completion of the work, it must be ensured by the agency that all the tools, materials and equipment are in place and have been cleaned. The permission must be signed by all signing authorities prior to closing it.

- Cancellation of work permit

A permit is cancelled when:

- Declaration of an emergency at the plant site;

- Any accident in the work permit area; and

- Permit conditions are violated.

Permits can also be suspended or put on hold for a short duration if the work conditions do not meet the safety protocols until such conditions are rectified. This is done by any signatory of the work permit.

Work Permit System Audits

It is recommended that HOD safety and trained auditors should be authorised by the plant or unit head to audit the work permit system. Auditing is required to ensure that permit preparation is adequately done in order to ensure that safety conditions and procedures are followed.

The functions of the auditors include:

- Examining the permits in order to check if they are correctly filled;

- Examining the execution of the job;

- Ensuring the prescribed frequency of the audit;

- Submitting the report of the audit to the plant or unit head because he is responsible for taking corrective actions as per the suggestions;

- Communicating the permit audit findings to both the issuer and the acceptor; and

- Cancellation of permit if the conditions are not found satisfactory.

The new IS 17893:2023 Work Permit System Code of Practice is extremely beneficial for organisations to standardise and improve their work permit system. The standard is available through the Bureau of Indian Standards website or can be downloaded by visiting this link.